Others also bought:

379,90 € *

T-Motor offers Electric Motors of the highest Quality and Industrial Grade.

First Class Efficiency and Reliability are the Result of excellent Processing and Components. Manufacturers of UAVs for industrial operations can hardly do without the brand T-Motor.

0

By selecting "Accept all", you give us permission to use the following services on our website: YouTube, Vimeo, ReCaptcha, Doofinder, Trustpilot, Google Analytics 4, Google Analytics (Universal Analytics), Google Ads Conversion Tracking. You can change the settings at any time (fingerprint icon in the bottom left corner). For further details, please see Individual configuration and our Privacy notice.

The settings you specify here are stored in the "local storage" of your device. The settings will be remembered for the next time you visit our online shop. You can change these settings at any time (fingerprint icon in the bottom left corner).

For more information on cookie lifetime and required essential cookies, please see the Privacy notice.

To view YouTube contents on this website, you need to consent to the transfer of data and storage of third-party cookies by YouTube (Google). This allows us to improve your user experience and to make our website better and more interesting. Without your consent, no data will be transferred to YouTube. However, you will also not be able to use the YouTube services on this website.

To view Vimeo contents on this website, you need to consent to the transfer of data and storage of third-party cookies by Vimeo.. This allows us to improve your user experience and to make our website better and more interesting. Without your consent, no data will be transferred to Vimeo. However, you will also not be able to use the Vimdeo services on this website.

To submit forms on this page, you need to consent to the transfer of data and storage of third-party cookies by Google. With your consent, reCAPTCHA, a Google service to avoid spam messages via contact forms, will be embedded. This service allows us to provide our customers with a safe way to contact us via online forms. At the same time, the service prevents spam bots from compromising our services. After you gave your permission, you might be asked to answer a security prompt to send the form. If you do not consent, unfortunately you cannot use the form. Please contact us in a different way.

To send data to Doofinder, you need to consent to the transfer of data and storage of third-party cookies by Doofinder.. This allows us to improve your user experience and to make our website better and more interesting.

Um Daten an Trustpilot zu übermitteln, ist Ihre Zustimmung zur Datenweitergabe und Speicherung von Drittanbieter-Cookies des Anbieters Trustpilot erforderlich. Dies erlaubt uns, unser Angebot sowie das Nutzererlebnis für Sie zu verbessern und interessanter auszugestalten.

Dies ist ein Webanalysedienst.

Erhobene Daten: anonymisierte IP Adresse, Datum und Uhrzeit des Besuchs, Nutzungsdaten, Klickpfad, App-Aktualisierungen, Browser Informationen, Geräte-Informationen, JavaScript-Support, Besuchte Seiten, Referrer URL, Standort-Informationen, Kaufaktivität, Widget-Interaktionen

Analyse

Processing company:Google Ireland Ltd, Gordon House, Barrow Street, Dublin 4,IE

Terms of use: LinkDies ist ein Webanalysedienst.

Erhobene Daten: anonymisierte IP Adresse, Datum uns Uhrzeit des Besuchs, Nutzungsdaten, Klickpfad, App-Aktualisierungen, Browser Informationen, Geräte-Informationen, JavaScript-Support, Besuchte Seiten, Referrer URL, Standort-Informationen, Kaufaktivität, Widget-Interaktionen

Analyse

Processing company:Google Ireland Ltd, Gordon House, Barrow Street, Dublin 4,IE

Terms of use: LinkMit dem Google Ads Conversion Tracking können wir unseren Werbeerfolg im Google Werbenetzwerk messen. Wir schalten Werbung im Google Werbenetzwerk, damit unsere Angebote besser gefunden werden. Wir versuchen dabei Werbung so optimal wie möglich zu gestalten. Auch um Werbekosten so gering wie möglich zu halten. Dies spiegelt sich in unseren Preisen wieder ;)

Erhobene Daten: zufallsgenerierte USER-ID

Marketing

Processing company:Google Ireland Ltd, Gordon House, Barrow Street, Dublin 4,IE

Terms of use: LinkWould you like to see these contents? Activate the desired contents for one session only or allow the website to remember these settings. Once you have given your consent, the third-party data can be loaded. For this, third-party cookies might be stored on your device. You can change these settings at any time (fingerprint icon in the bottom left corner). For further details, please see the Privacy notice.

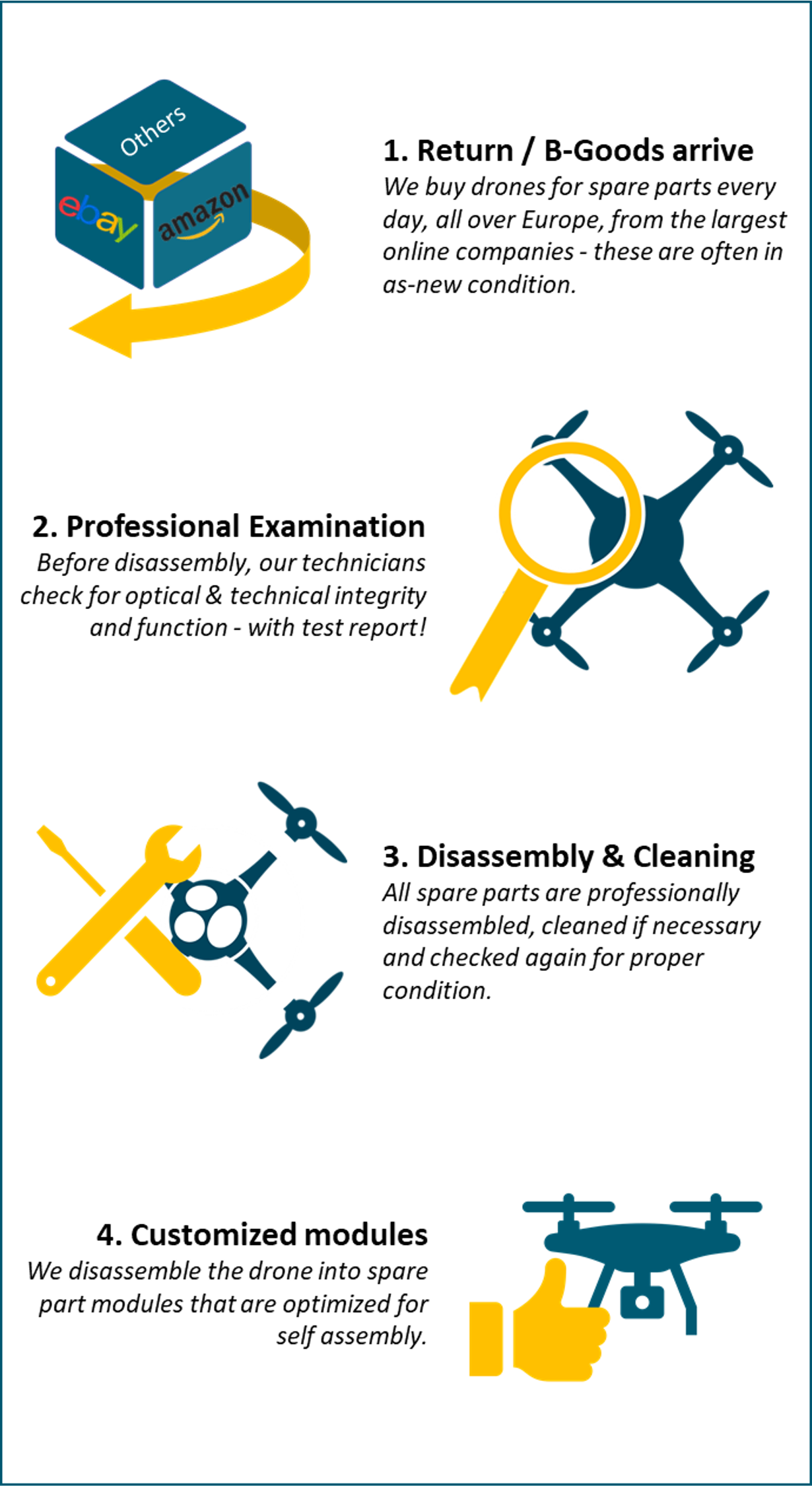

New goods (usually) come directly from the drone manufacturer and are produced as surplus in the same process as the drone.

Pros:

Cons:

Spare parts not directly from the manufacturer are listed as "used goods". They come often from good as new drones, B-goods or return units.

Pros:

Cons:

For the following products we charge a fixed cost of 100 €:

For the following products we charge a fixed cost of 150 €:

Too bad, now we have to go back to the glass ball or read in the coffee grounds to understand our visitors ...

Why do we have to do that? Quite simply, you have forbidden us to watch Your steps on our site with Google Analytics. That sounds dramatically to You, we know. But look at it: we do not even know who YOU are, we just see that SOMEONE looks at our pages, how he/she does that, how long this SOMEONE lingers on the respective pages, etc. We do not know who You are, whether You are male or female, how old You are, how Your weight is - no idea. Nor do we pass this data on to Google, we don not have them not at all! Nevertheless, this data of SOMEONE will provide us with valuable information about our site, we want You to like everything here, that You feel good and - of course - buy our products ...

So we can see where there are problems. If many visitors leave our site during the purchase process while choosing the payment method, we know that something is wrong and can improve it. Sounds good, right? Thats good for You and good for us. So it´s a win-win situation. So let us accompany You on Your way through our store. Deal?

Great, you got it! Now we can work better on our offer again!

Too bad, now we have to go back to the glass ball or read in the coffee grounds to understand our visitors ...

Why do we have to do that? Quite simply, you have forbidden us to watch Your steps on our site with Google Analytics. That sounds dramatically to You, we know. But look at it: we do not even know who YOU are, we just see that SOMEONE looks at our pages, how he/she does that, how long this SOMEONE lingers on the respective pages, etc. We do not know who You are, whether You are male or female, how old You are, how Your weight is - no idea. Nor do we pass this data on to Google, we don not have them not at all! Nevertheless, this data of SOMEONE will provide us with valuable information about our site, we want You to like everything here, that You feel good and - of course - buy our products ...

So we can see where there are problems. If many visitors leave our site during the purchase process while choosing the payment method, we know that something is wrong and can improve it. Sounds good, right? Thats good for You and good for us. So it´s a win-win situation. So let us accompany You on Your way through our store. Deal?

Great, you got it! Now we can work better on our offer again!